For projects in power, transportation, construction, and other industries, industrial Ethernet switches are needed because of their capability to build a reliable and secure network while withstanding harsh working environments. It is essential to choose the right industrial switch for your needs. Here are several factors you need to consider when using industrial switches.

Ease of Installation

Industrial switches work in very complex environments, including traffic control cabinets, factory floors, mines, etc. In these harsh application environments, the switches’ appearance design and installation methods need to meet special conditions to save costs and improve efficiency in network layout. For example, traffic control cabinets are placed next to roads and need to save as much space as possible, which requires industrial switches to be compact in design and easy to install. Therefore, to simplify installation and improve space utilization, industrial switches should provide flexible mounting options of DIN-rail, wall mount, and rack mount, so that you can choose suitable switches for different application environments.

Easy Management and Maintenance

- Managed vs. Unmanaged

Used for electricity networks in remote areas that are vulnerable to attack, industrial switches are expensive to manage and maintain. Although more expensive than unmanaged switches, managed industrial switches are optimal choices, offering advanced features that enhance your control of the network. With unmanaged switches, you can manage the network only based on feedback regarding links and activity from status LEDs. However, when you choose managed industrial switches, you will not only have the same status LEDs but also adjust your communication parameters to any setting you desire and let you monitor the network behavior in many different ways.

- Management Modes

In addition, management modes, especially secure remote management, are very important when industrial Ethernet switches are used in outdoor environments, which can save significant management and maintenance costs. For example, through SNMP, you can view a multitude of network statistics including the number of bytes transmitted and received; the number of frames transmitted and received; the number of errors and port status.

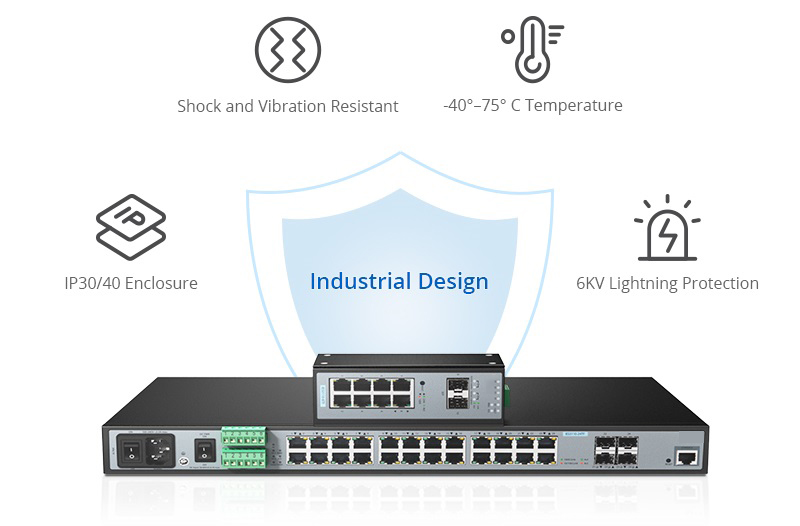

Durability

Many factories have high-temperature furnaces which generate a lot of dust and raise the temperature on factory floors. Traffic control cabinets would face rain, sleet, snow, dripping water, and corrosion. And sometimes, the data is generated within moving vehicles and trains. Such circumstances put high demands on the design and functions of industrial Ethernet switches. Therefore, the industrial Ethernet switches in the market are often equipped with IP30/IP40 aluminum industrial case protection, which allows them to work under the temperature range from -40° to 75°C, and provide a high level of immunity against electromagnetic interference and heavy electrical surges. High-level lightning protection is also needed to prolong the service life of industrial switches and ensure the normal transmission of data. Besides, industrial switches are often designed with dual redundant power inputs to avoid equipment failure caused by power failures.

Reliability

Since critical process control in industrial networks may rely on an Ethernet link, the economic cost of interruptions may be high, and high reliability is, therefore, an essential criterion for industrial Ethernet switches. Redundant ring technology and rapid self-recovery capability are needed features and necessary to prevent interruptions and external intrusions, which indicates the level of reliability with the industrial switches. In certain simple Ring networks, the recovery time of data links can be as fast as 10ms. To be more specific, the right switch can incorporate advanced ERPS (Ethernet Ring Protection Switching) technology and Spanning Tree Protocol (802.1s MSTP) into your industrial automation network to enhance system reliability and uptime in harsh environments.

Real-time Data Transmission

Network data transmission generates an inevitable delay, but industrial networks emphasize deterministic delivery of transmitted data to ensure the proper operation of important and wide-scale management such as traffic control. So when you purchase new switches, some advanced features are needed to consider to build the desired network.

QoS (Quality of Service) allows industrial switches to improve the performance of critical network traffic by prioritizing traffic or data flow according to its importance. With IGMP snooping, industrial switches can automatically forward multicast traffic to the links that have solicited them, which optimizes multimedia traffic delivery and ensure a netter network experience. VLANs allow a switch to logically group devices and isolate traffic between these groups, which can increase security measures and decrease network latency.

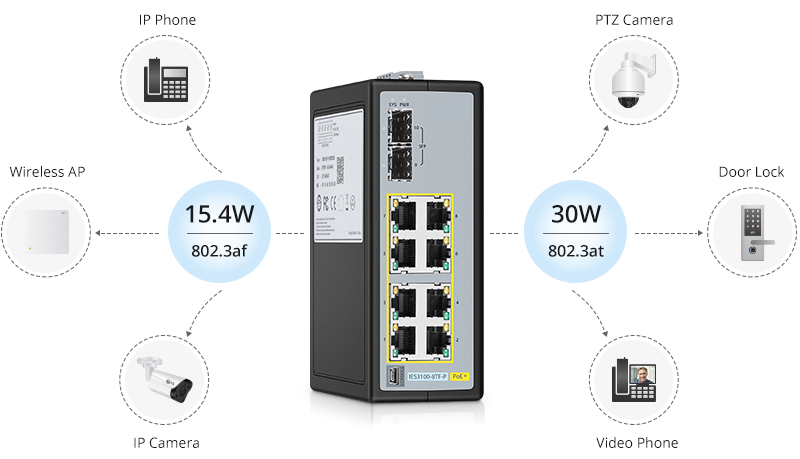

Compatibility

Connectivity is very important for projects in harsh conditions, like transportation, oil and gas, and city surveillance, hence the compatibility between industrial Ethernet switches and various devices is required. For example, in metro rail compartments, there are various devices, such as surveillance cameras, VoIP phones, and other IP devices, on-board vehicle control, and monitoring systems, all of which need to connect with industrial switches. Therefore, managed industrial switches that are compliant with IEEE 802.3af/at PoE standards are demanded in these industries because they are compatible with various devices and can match the power required by all the devices.

HANSUN

HANSUN