There are several differences between industrial switches and normal switches. They are mainly reflected in the function and performance below, and this is the reason why industrial switches are needed.

Physical Form Factor

Industrial switches generally use integrated metal shells, and fanless design to dissipate heat. Normal switches generally use plastic or metal shells, and use a fan to dissipate heat. The outer casing material of industrial switches has to be sturdy enough to resist vibration and shock.

Working Temperature

Industrial Ethernet switches can better adapt to poor climate conditions, including temperature, humidity, and so on. Industrial Ethernet has a wide operating temperature range of -40~75℃, it’s designed for high availability over long periods, and the operating temperature of a normal switch is only 0~50℃. Due to the different applicable temperature and components material, normal switches may have a shorter lifetime of 3-5 years, industrial Ethernet switches may be kept working for 10 years or more.

Installation

Because the normal switches are mostly used in homes and enterprises, the security requirements for the environment are not too high, the usual installation methods are desktop and rack installation. There are various ways often used when installing industrial switches, including rack, flat desktop, wall-mounted, and DIN rail-mounted installation. Generally, industrial switches use the DIN-rail installation, which is vibration and shock resistant, making them ideal for most industrial applications.

Power Supply

The power supply is a very important part of industrial switches. Power failures generally account for more than 35% of the equipment failure rate. To avoid the trouble of power failure, the industrial Ethernet switch generally supplies a dual power supply backup. while most normal switches in the market usually support a single power supply, which can only meet the basic requirements, it’s not suitable for industrial environments.

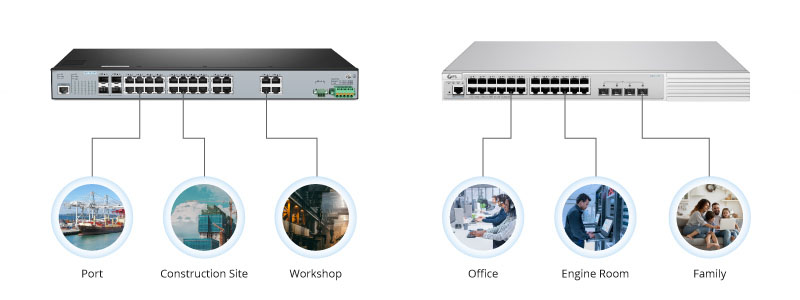

Application

Industrial network switches are built to work in harsh conditions such as manufacturing, transport, maritime, oil & gas, and mining. They are designed for high availability over long periods because downtime costs in industrial environments are often considerable.

HANSUN

HANSUN