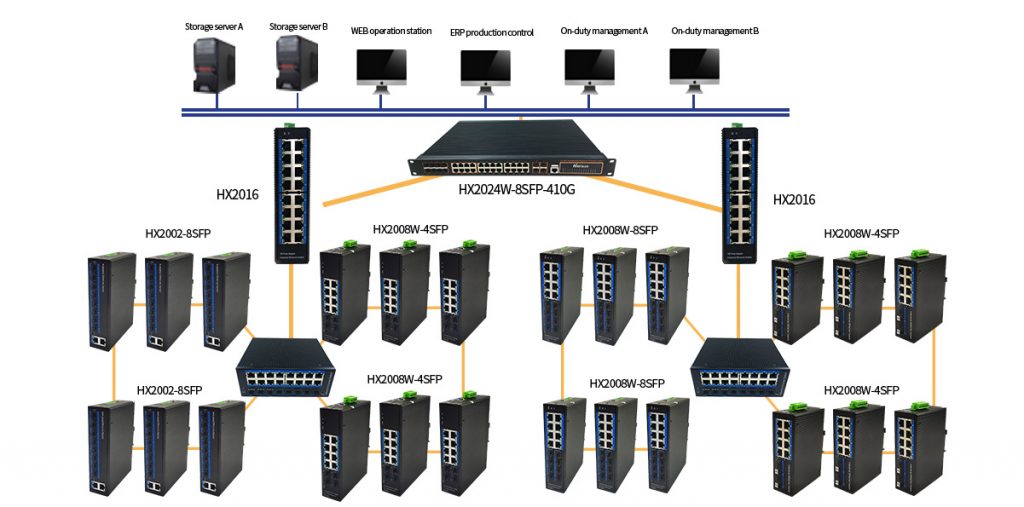

Automated steel production is an important prerequisite for improving the production efficiency of steel products, and effective monitoring of automated steel production lines is an important guarantee for ensuring the orderliness of automated steel production and the quality of steel products. In the iron and steel automation monitoring, the networking mode is directly connected to the automatic equipment, and the information collected by the sensors is fed back to the control station. At the same time, the control information of the control station is completely transmitted to the PLC and other automation equipment to realize the integration of the automation equipment and the sensor equipment. Unified management and automation. HANSUN has adopted

HX2024W-8SFP-410G, HX2016, HX2002-8SFP, HX2008W-4SFP, HX2008W-8SFP, industrial Ethernet switching institutions build internal communication networks in each workshop, and pass HX2024W-8SFP-410G inside the workshop

The Gigabit Industrial Ethernet constructs a ring network, and distributes the actual sites reasonably. The virtual local area network technology is used to logically isolate the data between the various vehicles to ensure the security of communication.

HANSUN

HANSUN