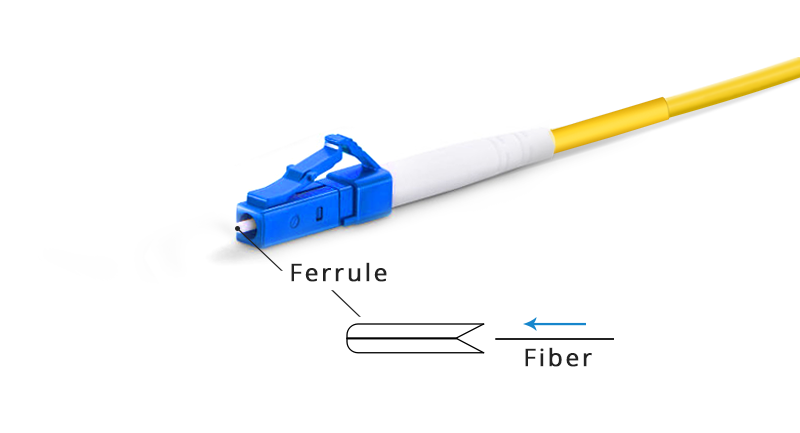

To put it simply, PC, UPC, and APC refer to the polish styles of the ferrules inside the fiber optic connectors, just as the following figure shows. The ferrule is the housing for the exposed end of a fiber, designed to be connected to another fiber, or into a transmitter or receiver. When connectors are installed on the end of a fiber, light is reflected back up the fiber towards the source, disrupting the signal. To increase the efficiency of fiber, engineers began to upgrade the surface of the critical point of attachment, and that’s how ferrule polish technologies are introduced. There are four connector polish types, three of which will be highlighted below.

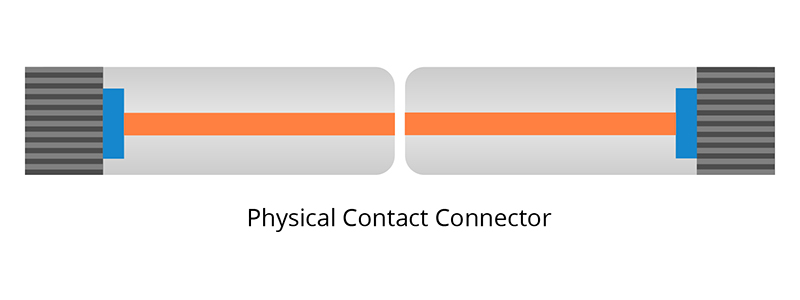

PC Fiber Connector

PC fiber connector refers to the connector that is polished in the physical contact style. It is the most common polish type that is found on OM1 and OM2 multimode fiber. PC fiber connector was generated to overcome the air gap between two surfaces from small imperfections in the original flat fiber connector. In PC fiber connector design, there is a slightly cylindrical cone head with the aiming to eliminate the air gap, so that the typical return loss in single mode applications is about -40dB, higher than the return loss of the original flat polish style (-14 dB or roughly 4%). Up to now, this polish style has been outdated and the evolution – UPC polish style has come into being.

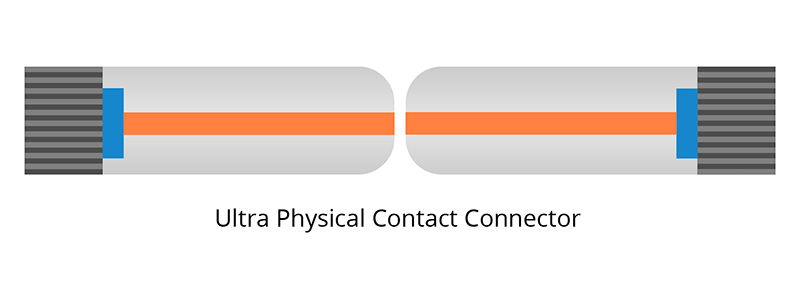

UPC Fiber Connector

UPC is the acronym for Ultra Physical Contact. It is an improvement of the PC fiber connector with a better surface finish after an extended polishing and the return loss is better than PC structure, nearly -50dB or higher. Though it has a relatively lower back reflection in comparison with the PC connector, it is not robust enough. Note that repeated connections and disconnections will bring about the degradation of the surface and ultimate performance.

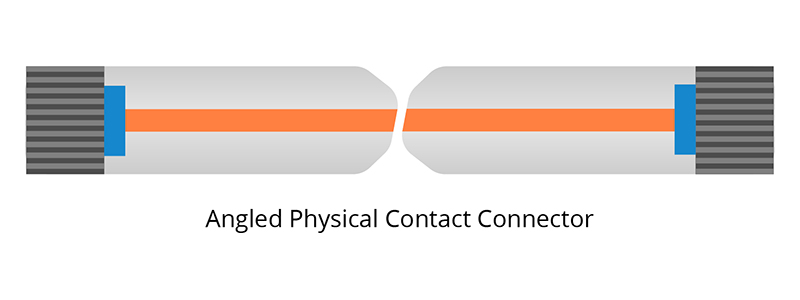

APC Fiber Connector

Out of the pursuit of lower back reflection, APC fiber connectors were developed. APC refers to Angled Physical Connect, the ferrule end face radius of which is polished at an 8°angel, minimizing the back reflection as a result. Since adding the angled end face, the reflected light will leak out into the cladding instead of staying in the fiber core. It should be noted that APC connectors should only be mated with other angled-polished connectors rather than non-angled polished connectors, or it will cause very high insertion loss. The optical return loss of APC connectors is -60dB or higher, better than the other connector types.

HANSUN

HANSUN